摘 要:准确计算凝析气井井底压力是正确预测产能、合理制订生产方案的关键,近年来凝析气井压力计算重点考虑黑油模型和组分模型的差异,而对优选气液两相管流压降模型的重要性却认识不足。为此,采用Govier-Fogarasi公开发表的94口凝析气井实验数据对工程常用的无滑脱模型、Hagedorn&Brown、Orkiszewski、Gray、Mukherjee&Brill、Hasan&Kabir分别按黑油模型和组分模型预测井筒压力。井底流压和压降梯度统计评价结果表明:两相流模型的选择对凝析气井井筒压力预测结果影响较大,而组分模型和黑油模型对部分两相流模型在一定条件下对凝析气井井筒压力计算产生影响;推荐使用Gray模型+黑油模型和Hagedorn&Brown模型+组分模型来预测凝析气井压力剖面,并给出了无滑脱模型的适用条件(液气比为0.5~5m3/104m3、产气量大于5×104m3/d);最后指出,采用组分数据计算凝析气井压力剖面时,其数据选择尤为重要,否则预测的误差会增大。该研究成果对于凝析气藏的高效开采具有重要的意义。

关键词:凝析气井 黑油模型 组分模型 气液两相流 井筒压力 气井压力剖面 计算

Calculation of the wellbore pressure of a condensate gas well

Abstract:Calculating the downhole pressure of a condensate gas well accurately is the key to predicting the well¢s productivity and making a reasonable production plan.In recent years,the calculation of condensate gas well pressure only focuses on the differences between the black oil model and the compositional model,which ignores the significance of the gas-liquid pipe flow pressure drop model optimization.Thus,the experimental data from 94 condensate gas wells published by Govier Fogarasi was used to predict the wellbore pressure of a slip-free model and five gas-liquid flowing models(Hagedorn&Brown。Orkiszewski.Gray,Mukherjee&Brill,and Hasan&Kabir).Statistical evaluation of downhole flowing pressure and pressure dropping gradients indicated that the selection of gas-liquid flow model affects the prediction results of wellbore pressure in a condensate gas well.Moreover,the compositional model and black oil model have an effect on the calculation of wellbore pressure in a condensate gas well by partial gas-liquid flow models under certain conditions.So Gray model+black oil model and Hagedorn&.Brown model+compositional model are recommended in predicting the pressure profile of a condensate gas well,and the application conditions of the slip-free model are provided,such as the liquid gas ratio ranges from 0.5 to 5m3/104m3,the gas production rate up to 5×104m3/d.Finally,it was pointed out that the data for calculating the pressure profile should be first selected,if not。the prediction error would be greater than expected.These research findings are of great significance to the high efficient development of condensate gas reservoirs.

Keywords:condensate gas well,black oil model,compositional model,gas-liquid flow,wellbore pressure,gas well profile,calculation

准确计算凝析气井井底压力是正确预测产能、合理制订生产方案的关键。近年来国内众多学者[1-5]发表一系列文章,认为采用考虑相变化的组分模型在相同条件下计算的井底流压明显优于黑油模型的预测结果。但文中只对比一种气液多相流压降模型或干气井压降模型,没有考虑不同压降模型对井底流压计算产生的误差,且仅给出了一个实例数据,也不具有普遍性。笔者采用Govier—Fogarasi[6-8]公开发表的94口凝析气井实验数据(原著实验井为l02口,扣除8口异常井),统计分析了流体物性模型(黑油模型和组分模型)和压降模型对凝析气井压降计算的影响,推荐了凝析气井井筒压降计算方法。

1 井筒流体物性参数计算

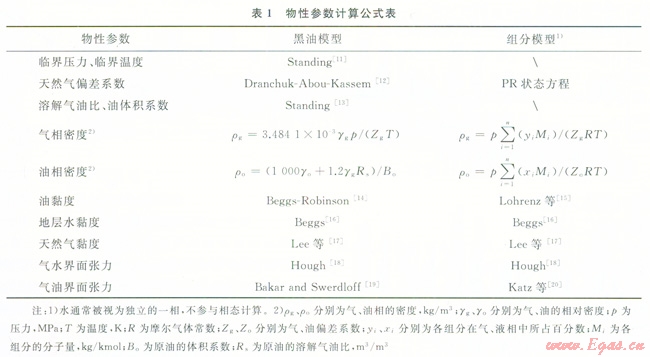

流体物性参数计算””是凝析气井井筒压降计算的基础。目前主要包括:①黑油模型。通过优选经验公式计算溶解气油比、天然气偏差系数、天然气体积系数等参数。②组分模型。通过状态方程计算流体密度、黏度、界面张力等。笔者所采用的主要计算模型如表1所示。

2 井筒压降预测统计分析

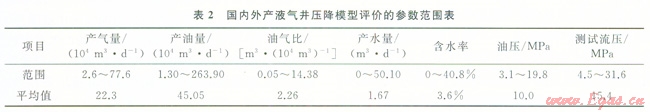

Govier-Fogarasi公开发表的94口凝析气井(全部为直井)主要参数如表2所示。

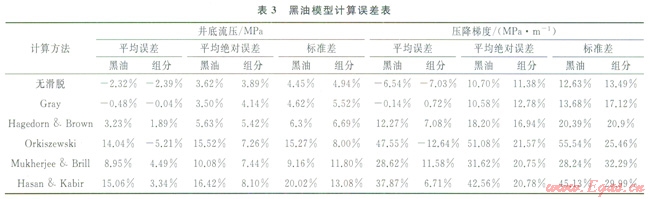

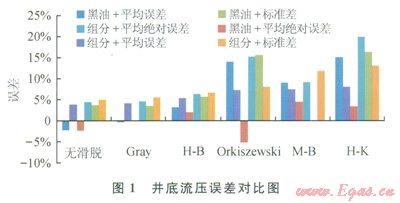

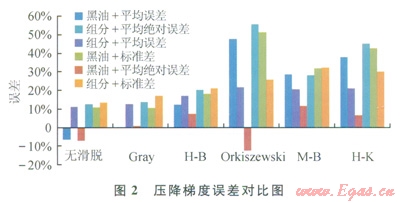

采用工程常用的无滑脱模型、Hagcdorn&Brown[21]、Orkiszewski[22]、Gray[23]、Mukherjee&Brill[24]、Hasan&Kabir[25]对上述凝析气井井底流压进行了计算,其误差统计结果如表3和图1、2所示。

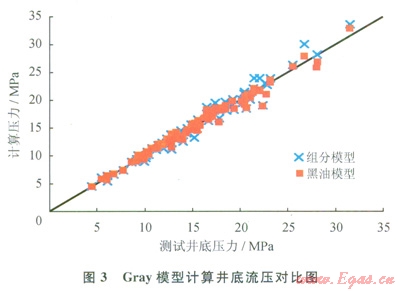

从统计误差看,Gray模型各项最小(图3),组分模型计算误差略大于黑油模型。这是由于Gray模型的持液率计算过程中考虑了凝析油的反凝析现象,而组分模型再引入相态方程,使凝析现象叠加导致组分模型计算压力较黑油模型对中性略差,误差增加。因此推荐Gray模型按黑油模型计算凝析气井井筒压力。

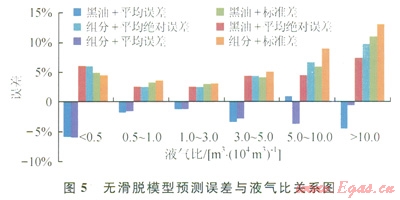

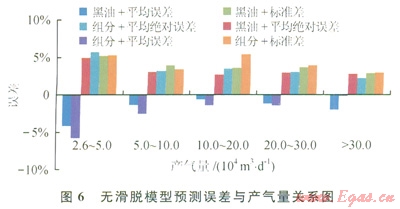

无滑脱模型各项误差次之(图4),组分模型计算误差大于黑油模型,是由于Govier-Fogarasi用的凝析气井液气比为0.05~14.4m3/104m3,从黑油模型对所选模型(无滑脱、Gray和Hagedorn&Brown没有划分流型)计算流型看:Mukherjee&Brill和Orkiszewski所有井井简全部为段塞流,Hasan&Kabir预测结果除5井次出现分散泡状流以外,其余井全为环状流。段塞流为一段气一段液,而环状流主要靠气相中携带的液滴和气相与管壁液膜的摩擦带液。因此两种流型的滑脱损失均较小,可以采用无滑脱模型计算压降。从分段液气比看,液气比小于0.5m3/104m3,误差较大,这主要是由于气液比极高,举升压降极小,13口压降梯度平均为1.74MPa/1000m,导致井底流压(13口井底流压平均13.4MPa)较小,即使计算的井底流压误差较小因井底流压测压值较小而误差较大。随着液气比的增加,各项误差逐渐增加(图5)。现考虑各项误差限为5%,采用无滑脱模型的液气比范围为0.5~5m3/104m3,并对该气液比条件下的产气量进行了分段统计如图6所示,随着产气量的增加,各项误差逐渐下降。因此无滑脱模型按黑油计算适用条件为:液气比0.5~5m3/104m3,产气量大于5×104m3/d,井底流压误差小于5%。

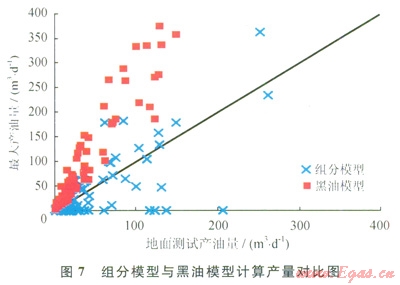

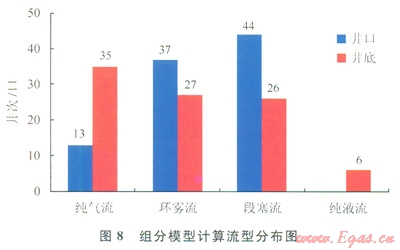

从所选的4个气液两相流模型(Hagedorn&Brown、Orkiszewski、Mukherjee&Brill、Hasan&Kabir)看,Hagedorn&Brown模型各项误差最小,按组分模型计算的误差明显小于黑油模型。为了讨论组分模型对流型、凝析油流量的影响,现选用误差较小且考虑流型的Mukherjee&Brill进行统计分析。分别按组分模型和黑油模型计算的井筒最大产油量如图7所示,组分模型计算的井筒最大产油量明显较地面测试产油量大得多,而按黑油模型计算的产油量明显偏小,说明随井筒向上流动过程中,压力温度降低导致了凝析油的析出,与实际情况一致;井筒流量的改变使流型发生明显变化,黑油模型计算的井筒流型全部为段塞流,组分模型计算时井底高温高压凝析油未析出或析出较少,以纯气流、环雾流和段塞流为主,所占井次比例依次下降,而井口主要流型未变,但各流型的井次比例呈明显的反比关系(图8),使按组分模型计算的各项误差明显小于黑油模型。

综上所述,两相流模型的选择对凝析气井井筒压力预测的影响较大,而组分模型和黑油模型对部分两相流模型和在一定条件对凝析气井井筒压力计算产生影响。推荐Gray模型+黑油模型和Hagedorn&Brown模型+组分模型来预测凝析气井压力剖面;液气比0.5~5m3/104m3、产气量大于5×104m3/d时,推荐采用无滑脱模型来计算压力剖面。

3 组分模型计算时存在的主要问题

组分模型计算流体物性时,需要知道该井测试条件下流体组成,而该数据往往不可获得。下面就流体组成数据的选取进行分析。

1)凝析气藏相图。根据凝析气藏不同开发阶段需要进行测试,但该数据只能反映某时段凝析气藏流体的整体情况,而单井流体组成具有特殊性(各井产出流体气油比、含水率与整个气藏不一定相同)和时效性(各井随开采时间的增加流体组成不同),采用凝析气藏相图与单井实际情况存在较大差异。

2)井筒压力测试时气分析数据。该数据取样点一般为井口或分离器内气态气,基本不含重组分或重组分极少,不能代表该井实际流体组成。

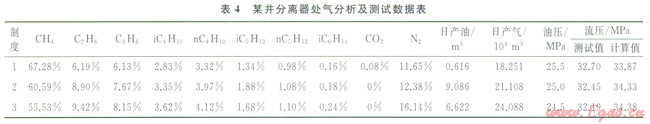

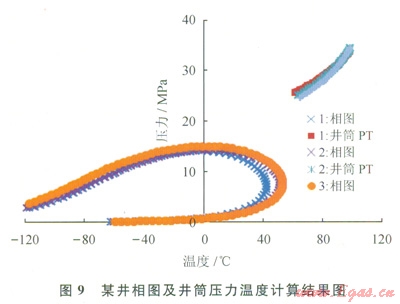

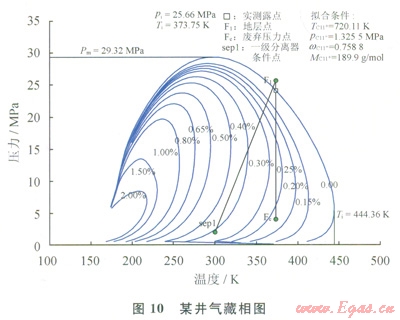

某井试油时分离器处气分析及测试数据见表4。依据各制度测试的组分数据按PR状态方程计算的相图及井筒压力温度见图9。3个制度下计算的井筒压力温度远大于相图的两相区,即井筒内为纯气态。但从气藏相图(图10)看,井筒压力温度应为两相区,这主要是由于计算所采用的组分数据为分离器内的气态气(低压),重组分含量低,与气藏相图气液两相时组分数据差异大所致。分离器的气组分随着油嘴尺寸的增加(产气量增大),井口油压(25.5~24.5MPa)依次降低0.5MPa,轻烃逐渐下降,重组分逐渐增大,使其相图逐渐右移。即相图差异也较大。由于井筒油气比(0.034~0.43m3/104m3)极小,其预测的井底流压与实测值差1.2~2.2MPa,平均误差5.39%。

4 结论

1)两相流模型的选择对凝析气井井筒压力预测的影响较大,而组分模型和黑油模型对部分两相流模型和在一定条件对凝析气井井筒压力计算产生影响。

2)94口凝析气井井筒压力计算表明:推荐Gray模型+黑油模型和Hagedorn&Brown模型+组分模型预测凝析气井压力剖面;无滑脱模型适用条件是液气比为0.5~5m3/104m3、产气量大于5×104m3/d。

3)采用组分数据计算凝析气井压力剖面时,气组分数据选择尤为重要,町能导致井筒实际流体与计算流体不一致,使预测的误差增大。

参考文献

[1]喻西崇,胡永全,赵金洲,等.凝析气井井眼压降和温降计算研究[J].钻采工艺,2002,25(1):37-39.

YU Xichong,HU Yongquan,ZHAO Jinzhou,et al.Cornputational analysis of borehole pressure drop and temperature drop for gas condensate wellEJ].Drillin9&.Production Technology,2002,25(1):37-39.

[2]朱炬辉,胡永全,赵金洲,等.相态变化影响下的凝析气井井筒压力变化计算分析[J].大庆石油地质与开发,2006,25(6):50-52.

ZHU Juhui,HU Yongquan,ZHAO Jinzhou,et al.Calculation on change in borehole pressure of gas condensate well at the condition of phase change[J].Petroleum Geology&Oilfield Development in Daqing,2006,25(6):50-52.

[3]常志强.考虑多相流体复杂相态变化的凝析气井生产动态分析方法[D].成都:西南石油学院,2005.

CHANG Zhiqiang.Method for analysis of multiphase cornplex phase behavior of condensate gas well production dynamic considerations[D].Chengdu,Southwest Petroleum Institute,2005.

[4]苏如海,张正茂.PR状态方程在凝析气井井筒计算中的应用[J].内蒙古石油化工,2006,(3):128-129.

SU Ruhai,ZH ANG Zhengmao.The application of PR EOS in wellbore calculation of condensate wellEJ].Inner Mongolia Petrochemical Industry,2006(3):128-129.

[5]何志雄,孙雷,李士伦.凝析气井井筒动态预测方法[J].中国海上油气:地质,1998,30(5):66-69.

HE Zhixiong,SUN Lei,LI Shilun.Method for prediction of borehole performance in condensate gas well[J].China Offshore Oil and Gas:Geology,l998,30(5):66-69.

[6]GOVIER G W,FOGARASI M.Pressure drop in wells producing gas and condensate[J].Journal of Canadian Petroleum Technology,1975,14(4):28-41.

[7]PEFFER J W,MILLER M A,HILL A D.An improved method for calculating bottomhole pressures in flowing gas wells with liquid presentEJ].SPE Journal,1988,3(4):643-655.

[8]SADEGH A A.An integrated hydrodynamic/PVT vertical wellbore model for twcr-phase natural gas/liquid systems[D].University Park:Pennsylvania State University Press,2006.

[9]李士伦.天然气工程[M].北京:石油工业出版社,2000.

LI Shilun.Natural gas engineering[M].Beijing:Petroleum Industry Press,2000.

[10]BRILL J P,MUKHERJEE H.Multiphase flow in wells[M].//SPE Monograph Series(Vol.17),Richardson Tex:Henry L.Doherty Memorial Fund of AIME,Society of Petroleum Engineers,1999.

[11]NUMBERE D,BRIGHAM W,STANDING M B.Correlations for physical properties of petroleum reservoir brines[R].Stanford:Stanford University,1977.

[12]DRANCHUK P M,ABU K H.Calculation of z factors for natural gases using equations of state[J].Journal of Canadian Petroleum Technology,1975,14(3):33-36.

[13]STANDING M B.A pressure-volume-temperature correlation for mixtures of California oil and gases[C]//Drilling and Production Practice,1947.New York:American Petroleum Institute,1947.

[14]BEGGS H D,ROBINSON J R.Estimating the viscosity of crude oil systems[J].Journal of Petroleum Technology,1975,27(9):1140-1141.

[15]LOHRENZ J,BRAY BG,CLARK C R.Calculating viscosities of reservoir fluids from their compositions[J].Journal of Petroleum Technology,1964,16(10):1171-1176.

[16]BEGGS H D.Production optimization using nodal analysis[M].Tulsa:OGCI Publication,1991.

[17]LEE A L,GONZALEZ M H,EAKIN B E.The viscosity of natural gases[J].Journal of Petroleum Technology,1966,18(8):997-1000.

[18]HOUGH E W,RZASA M J,W00D B B.Interfacial tensions at reservoir pressures and temperatures[J].Journal of Petroleum Technology,l951,3(2):57-60.

[19]HOUGH E W.Correlation of interracial tension of hydrocarbons[J].SPE Journal,l966,6(4):345-349.

[20]KATZ D LHandbook of natural gas engineering[M].New York:McGraw Hill Book Company Inc.,1959.

[21]HAGEDORN A R,BROWN K E.Experimental gtudy of pressure gradients occurring during continuous two phase flow in small-diameter vertical conduits[J].Journal of Petroleum Technology,1965,17(4):475-484.

[22]0RKISZEWSKI J.Predicting two-phase pressure drops in vertical pipes[J].Journal of Petroleum Technology,1967,19(6):829-838.

[23]GRAY H E.Vertical flow correlation in gas wells[S].User Manual for API 14B Subsurface Controlled Safety Valve Sizing Computer Program,2nd edition,API Appendix B,1978:38-41.

[24]MUKHERJEE H,BRILLJ P.Pressure drop correlations for inclined two-phase flow[J].Journal of Energy Resource Technology,1985,107(4):549-554.

[25]HASAN A R,KABIR C S.Two phase flow in vertical and inclined annuli[J].International Journal of Multiphase Flow,1992,l8(2):279-293.

本文作者:刘永辉 任桂蓉 薛承文 关志全 胡利平

作者单位:西南石油大学石油与天然气工程学院

中国石油新疆油田公司工程技术研究院

中国石油阿南油气田公司蜀南气矿

中国石油西南油气田公司川中油气矿

您可以选择一种方式赞助本站

支付宝转账赞助

微信转账赞助